Low Voltage and Medium Voltage Fuses - Types and Their Applications

Fuses are an essential part of power systems, providing protection against overcurrent, short circuits, and electrical faults. They act as the first line of defense, ensuring that excess current does not damage critical equipment. Depending on the voltage level, fuses are categorized as Low Voltage (LV) fuses and Medium Voltage (MV) fuses. These fuses are used in industrial, commercial, and utility applications to protect transformers, motors, switchgear, and distribution networks.

Types of Fuses in Power System:

A fuse is a protective device that contains a metal wire or strip that melts when excessive current flows through it. This breaking of the circuit prevents damage to electrical components and reduces the risk of fire or system failures.

Fuses can be classified based on voltage ratings, application, interrupting rating, and construction types. The primary classifications are:

Low Voltage (LV) Fuses:

Low voltage fuses play a crucial role in protecting electrical systems and devices from potential hazards such as short circuits, overloads, and other unexpected electrical events. These fuses are specifically designed for low voltage applications, typically up to 1,000 volts (V) for alternating current (AC) and 1,500 volts (V) for direct current (DC).

Low voltage fuses are classified in general purpose fuses, each designed for specific applications and protection levels. The most used types include:

-

Cartridge Fuses:

Cartridge fuses consist of a cylindrical body with metal end caps, which make contact with the fuse holder. These fuses are available in both fast-acting and time-delay versions, depending on the application. Fast-acting cartridge fuses rapidly interrupt the circuit when an overcurrent occurs, while time-delay fuses allow for a short period of increased current before breaking the circuit, which is useful in scenarios where temporary surges are common. They are widely used in industrial control circuits, motor protection, and power distribution systems due to their reliability and ease of replacement.

-

Blade Fuses:

Blade fuses are compact, plug-in fuses commonly used in automotive and low-voltage DC applications. They have a plastic housing with two metal prongs that fit into a fuse holder, ensuring easy installation and replacement. Blade fuses are color-coded based on their ampere rating, making identification simple. Available in fast-acting and slow-blow variants, in vehicles they protect against overcurrent in various systems, ranging from the headlights and windshield wipers to the car’s internal computer systems.

-

High Rupture Capacity (HRC) Fuses:

High Rupturing Capacity (HRC) fuses are designed to withstand high fault currents while preventing explosions or damage to electrical systems. They feature a ceramic or glass enclosure filled with arc-quenching materials, such as silica sand, which helps suppress the arc when the fuse operates. Commonly used in manufacturing plants, power plants, and large commercial facilities due to their high breaking capacity and reliability. Their robust design protects against both overloads and short circuits, ensuring the safety of expensive machinery and preventing potential downtime.

We previously published a blog on the steps to choosing the right fuse for power system protection. Checked it out to grasp the information available in this blog.

In addition to general-purpose fuses, UL-classified fuses are categorized based on their voltage rating, interrupting capacity, and specific industrial applications. These include:

1. Class-L Fuse

Class L fuses are designed for high-current applications, rated at 600V with nominal current ratings between 601A and 6000A. With an interrupting capacity of 200kA, they are commonly used for switchboard mains and feeders, large motor branch circuits, power circuit breakers, and main service entrances, providing reliable short-circuit protection in industrial and commercial power distribution systems.

2. Class- H Fuse:

Class H fuses are general-purpose fuses with a voltage rating of 250V or 600V and an interrupting capacity of 10kA. They are available in both time-delay and fast-acting variants but do not have a current-limiting feature. Due to their low interrupting rating, they are typically used in less critical applications and have largely been replaced by higher-rated fuse classes for improved safety.

3. Class- R Fuse:

Class R fuses are current-limiting fuses designed to provide enhanced short-circuit protection in industrial applications. They are rated for 250V or 600V with a high interrupting capacity of 200kA, making them significantly safer than standard Class H fuses.

They are available in two categories:

- RK1 fuses: Provide superior current-limiting protection and are used in highly sensitive circuits where arc flash mitigation is crucial.

- RK5 fuses: Offer moderate current-limiting characteristics and are used in motor circuits, feeder protection, and general-purpose applications.

Both RK1 and RK5 fuses include a rejection feature, preventing the accidental use of lower-rated Class H fuses in their place.

4. Class- J Fuse:

Class J fuses are high-performance current-limiting fuses with a 600V rating and a 200kA interrupting capacity. They are commonly used in motor control centers (MCCs), industrial switchgear, and transformer protection. These fuses are compact in size and provide excellent short-circuit and overload protection, making them ideal for high-reliability applications.

| Types | Construction/Design | Voltage Rating | Ampere Range | AIC | Applications | Key Features |

|---|---|---|---|---|---|---|

| Cartridge Fuse | Cylindrical body with metal end caps | Up to 1,000V AC / 1,500V DC | Wide range (few hundreds) | 10–100 kA (typical) | Industrial control, motors, distribution | Available in fast-blow and time-delay types |

| Blade Fuse | Plastic body with two prongs | 12–32V DC (Automotive) | 1–40A | 1–2 kA | Automotive circuits, electronics | Color-coded, compact, easy replacement |

| HRC Fuse | Ceramic/glass body with silica filling | Up to 1,000V | Up to 800A | 80–120 kA | Industrial, commercial, switchgear | High breaking capacity, arc-quenching |

| Class L | Heavy-duty, current limiting | 600V | 601–6000A | 200 kA | Main services, switchboards | Used in high-current circuits |

| Class R (RK1 / RK5) | Current-limiting, rejection type | 250V / 600V | 1–600A | 200 kA | General protection, motor circuits | RK1 = higher performance, RK5 = general-purpose |

| Class H | Non-current limiting | 250V / 600V | 1–600A | 10 kA | Non-critical applications | Obsolete in many cases |

| Class J | Compact, current limiting | 600V | Up to 600A | 200 kA | MCCs, transformers, panels | Space-saving, high protection |

MEDIUM VOLTAGE (MV) FUSES:

Medium Voltage (MV) fuses are protective devices used to interrupt overcurrent and short circuits in electrical systems operating at voltages between 1 kV and 36 kV. These fuses are designed to provide fast and reliable protection for transformers, switchgear, motors, and other medium-voltage equipment by safely disconnecting faulty circuits.

Medium voltage fuse types vary based on construction and application. One widely used type is the expulsion fuse or drop out fuse:

-

Expulsion Fuse:

Expulsion fuses are non-current limiting fuses that use a gas-expelling mechanism to extinguish the arc created during a fault. When a fault occurs, the fuse element melts, and the arc generated causes materials inside the fuse to produce gases that help "blow out" or expel the arc through venting. These fuses are commonly used in overhead distribution systems and pole-mounted transformers due to their cost-effectiveness and simplicity.

In addition to construction-based classifications, MV fuses are also categorized by performance ratings defined by standards, such as E-rated, R-rated, and C-rated fuses:

-

E- Rated Fuses (Power Fuse):

E-rated fuses are standardized medium voltage fuses typically used for the protection of transformers, feeders, and general-purpose equipment. These fuses are rated according to ANSI standards and provide full-range protection, meaning they can interrupt both low and high fault currents. E-rated medium voltage fuses are required to operate within specific time limits based on their rating and the level of overcurrent. E-Rated fuses normally take about twice of their numeric rating for it to begin to respond. For fuses rated 100E or below, they must open within 300 seconds (5 minutes) when exposed to an RMS current of 200% to 240% of their continuous current rating. For fuses rated above 100E, they are expected to clear the circuit within 600 seconds (10 minutes) when subjected to an RMS current between 220% and 240% of their continuous rating. They are commonly used in MV Utility Transformer protection.

-

R-Rated Fuses:

R-rated fuses are current-limiting, time-delay fuses designed specifically for the protection of medium voltage motors and motor controllers. These fuses can withstand high inrush currents associated with motor starting without blowing, while still providing protection against short-circuits. R-rated medium voltage fuses are designed to open within 15 to 35 seconds when exposed to an RMS current that is 100 times their 'R' rating. For instance, a fuse with a 2R rating must interrupt the circuit within that time frame when subjected to a current of 200 amperes (i.e., 2 × 100). This time-delay characteristic allows the fuse to tolerate motor starting currents without nuisance tripping while still offering protection against short circuits.

Check out this blog to find the steps to choose the right circuit breaker based on your requirements.

| Category | Type | Construction / Design | Voltage Rating | Ampere Range | AIC | Applications | Key Features |

|---|---|---|---|---|---|---|---|

| Medium Voltage (MV) | Expulsion Fuse | Arc-expelling (gas release), open vent | 1–36 kV | Depends on use (typically 1–200 A) | Non-current limiting (lower) | Overhead lines, pole transformers | Cost-effective; requires periodic maintenance |

| E-Rated Fuse | Current-limiting, full-range | 2.4–34.5 kV | 1E–200E+ | Up to 63 kA | Transformers, feeder protection | Time-dependent response; good transformer protection | |

| R-Rated Fuse | Time-delay, current-limiting | 2.4–15.5 kV | 2R–24R+ | 50–63 kA | MV motor protection | Designed to delay through motor inrush currents |

CURRENT LIMITING FUSE (CLF):

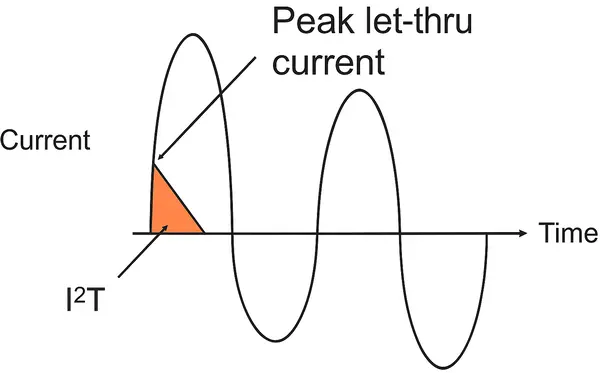

Current-limiting fuses are designed to interrupt fault currents extremely quickly, well before the first peak of the current waveform, typically within a quarter cycle. This rapid operation not only interrupts the fault but also limits the let-through energy (I²t) and peak let-through current (Ip), significantly reducing thermal and mechanical stress on downstream components.

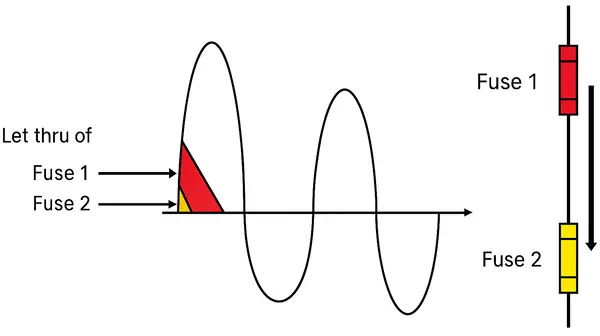

For two current limiting fuses in series, to perfectly coordinate the downstream fuse. The let-through characteristic of the smaller downstream fuse (fuse 1) has to be such that it begins to clear the fault very early back here and it completely clears the fault before the 1st 0 crossing. Fuse 2 has to operate so quickly that it limits the current to such a low value and lets through such a small amount of thermal energy (I²T energy) that its well below what it takes the upstream fuse to melt.

When a high-level fault occurs, the element melts almost instantly, and the arc is extinguished by the sand, which absorbs the heat and prevents arc propagation. These fuses are available in both low voltage (LV) and medium voltage (MV) applications Current-limiting fuses are categorized based on their interrupting rating—typically up to 200 kA for LV fuses and 63 kA or more for MV fuses. Their precise fault-clearing ability also supports selective coordination and minimizes the risk of cascading outages, making them vital for use in critical infrastructure, industrial plants, and dense electrical networks.

Series-rated fuses are an effective way to enhance electrical protection by strategically pairing devices with different interrupting capabilities. In a series-rated configuration, two or more protective devices (typically a fuse and a circuit breaker) are connected in series so that the upstream device clears high fault currents, while the downstream device manages lower fault levels. It enhances protection in power systems by combining the strengths of multiple devices. This approach ensures that each fuse addresses specific current levels and fault scenarios, providing a layered defense mechanism. The series configuration maximizes system reliability by preventing overloading and mitigating cascading failures. Additionally, it improves the overall protection coordination, ensuring that faults are isolated effectively without damaging downstream components, thus safeguarding the integrity of the power system. Check out our blog, for a more detailed understanding of how series protective devices work.

Significance of Fuses in Short Circuit, Arc Flash and Protection Coordination Studies:

Fuses play a critical role in power system studies by directly influencing the outcomes of short circuit analysis, arc flash assessments, and protection coordination. In short circuit studies, fuses must be correctly rated to interrupt the maximum fault current without damage, ensuring the system can isolate faults safely. During arc flash studies, current-limiting fuses significantly reduce incident energy by clearing faults in less than half a cycle, thus lowering the arc flash hazard category and enhancing personnel safety. In protection coordination studies, fuses are carefully selected and coordinated with upstream and downstream devices to ensure that only the nearest protective device operates during a fault, minimizing system disruption. Properly modeled fuse characteristics, such as TCC (Time-Current Characteristic) curves, are essential for accurate simulation and analysis, helping engineers optimize system performance and safety across various fault scenarios.

Fuses, both in low and medium voltage applications, are indispensable components in modern electrical power systems. Their ability to provide fast and reliable protection plays a vital role in maintaining system stability, minimizing equipment damage, and ensuring operational continuity in the face of faults such as short circuits and over currents.

Engineers at AllumiaX are experts in identifying the opportunities to maximize protection, reliability and performance of low voltage and medium voltage industrial and commercial power system studies. We specialize in delivering comprehensive power system studies, including short circuit analysis, arc flash hazard assessments, and protection coordination. Through our expertise, we help industries achieve not only compliance and safety but also long-term efficiency and resilience in their electrical infrastructure.Contact AllumiaX today. Our team of engineers and technicians will provide the solutions you need.

Stay Sharp & Join our Mailing List!

Subscribe to Allumiax Blog for updates on power system studies, tips, guides and insights on electrical engineering from industry leaders.