NFPA 70E (2024 EDITION) – EVERY MAJOR CHANGE EXPLAINED

A Complete, Practical, and In-Depth Analysis for Electrical Safety Programs

The NFPA 70E 2024 Edition advances workplace electrical safety, building on its 1979 origins as support for OSHA’s mission. The latest update improves clarity with better definitions, stronger risk assessment guidance, refined safe work practices, and enhanced rules for normal operating conditions, label durability, and hearing protection within arc-flash boundaries, helping organizations reduce electrical incidents and align programs with current best practices.

Background of NFPA 70E – How the Standard Evolved Into Today’s Framework

NFPA 70E was developed after OSHA identified the need for a consensus-based standard focused on electrical safety practices, procedures, and maintenance—areas not covered by the NEC®, which governs installation. NFPA formed its first committee in 1976, leading to what is now NFPA 70E.

NFPA 70E (Standard for Electrical Safety in the Workplace) evolved in early editions (1979–2000) by establishing foundations: 1979 covered installation safety; 1981 added safety-related work practices; 1983 included maintenance requirements; 1995 aligned with 1993 NEC, introducing limits of approach and early arc-flash concepts; 2000 added Part IV (special equipment) and strengthened PPE guidance.

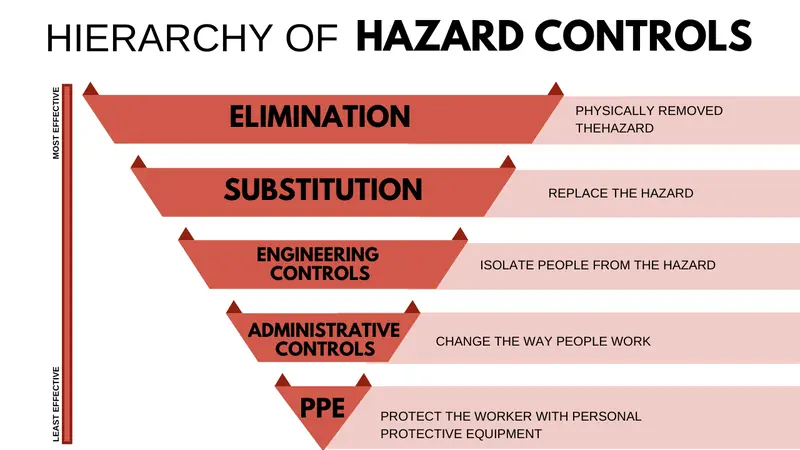

The modernization phase (2004–2018) shifted to risk-based thinking: 2004 renamed/reorganized with work practices upfront and energized work permits; 2009/2012 integrated arc-flash updates, expanded annexes (D,F,J,M,N,O), added hazard ID/risk-assessment; 2015 prioritized risk assessment over hazard analysis, defined normal operation, introduced task-based PPE tables, required maintenance considerations; 2018 added human factors (Annex Q), hazard elimination priority, refined ESWC/PPE terms.

What NFPA 70E-2018 Established Before the 2024 Edition

NFPA 70E-2018 introduced foundational changes to arc-flash labeling, task-based PPE selection, and risk assessment practices that continue to influence today’s requirements. Read our in-depth blog on 5 Major Changes in NFPA 70E 2018, Including New Arc-Flash Label Requirements to understand how these changes reshaped electrical safety programs worldwide.

Recent editions (2021–2024) enhanced clarity/tech alignment: 2021 consolidated programs in Article 110, added Article 360 (Capacitors)/Annex R, updated arc-flash to IEEE 1584-2018; 2024 strengthened normal operating conditions, labeling durability, definitions, risk assessment, maintenance, shock/arc-flash boundaries—preserving core framework.

Major Changes and Key Updates in NFPA 70E – 2024 Edition

1. Global Changes to the NFPA 70E – 2024 Edition

The 2024 edition of NFPA 70E applies several global updates, including consistent use of the term “electric shock,” removal of the leather-only restriction for protectors, the addition of a scope section in every article, and the consolidation of all definitions into Article 100 to improve clarity and usability across the standard.

2. Revisions to Article 90 – Introduction and Scope Clarifications

The 2024 edition updates Article 90 by adding a formal scope section (90.1), resulting in renumbering and renaming the former Introduction as 90.3 Workplaces Covered and Not Covered. It also clarifies in 90.5(C) that undated referenced standards apply to the latest edition, ensuring use of current references.

3. Updated Definitions in Article 100

The 2024 edition updates Article 100 to improve clarity and usability by consolidating all definitions into one location and clarifying that definitions followed by an article number in parentheses apply only to that article (e.g., Battery Effect (310)). Definition titles were revised to enhance electronic searchability, with commonly used terms added in parentheses, such as Boundary, Arc Flash (Arc Flash Boundary). The definition of “Protector” was refined to remove material-specific wording, and new definitions for ionizing and nonionizing radiation were added to better distinguish radiation-related hazards in electrical environments.

4. Key Changes in Article 110 – General Requirements for Electrical Safety-Related Work Practices

Article 110 introduces structural and procedural updates to enhance electrical safety-related work practices. The updated scope (110.1) clarifies coverage of general electrical safety requirements and aligns with the standard’s format. Sections 110.3 and 110.4 are consolidated into 110.2, detailing requirements for achieving and applying an Electrically Safe Work Condition (ESWC), with employers now required to establish a formal ESWC policy prioritizing hazard elimination. Documentation of the policy may be included in safety programs or management systems. Conditions requiring ESWC are clarified, including updates to terminology, equipment rating requirements, and new exceptions for operating energized disconnecting means and equipment below 50V. Job safety planning (110.3) now mandates an emergency response plan. Qualified person requirements (110.4) are refined: “special” is replaced with “applicable” to focus on task-relevant techniques, and “can” is replaced with “shall” to reinforce mandatory qualifications.

5. Revisions to Article 120 – Establishing an Electrically Safe Work Condition

Article 120 updates enhance the accuracy and thoroughness of procedures for establishing and verifying an Electrically Safe Work Condition (ESWC). Locating sources of supply (120.5(A)(1)) now includes a note highlighting a commonly overlooked hazard: the neutral conductor may continue to carry current even after phase conductors are de-energized, reinforcing the need to identify all possible sources of electrical energy. Stored energy requirements (120.5(B)(2)) clarify that stored mechanical energy extends beyond springs and must be relieved or blocked “to the extent that the circuit cannot be unintentionally energized,” ensuring comprehensive control of all energy sources. The process for establishing and verifying ESWC (120.6), renumbered from 120.5, includes a refinement in step 7: workers must test each phase conductor or circuit part at each point of work, emphasizing verification precisely where work occurs and preventing errors in multi-section equipment or systems with multiple compartments.

6. Major Updates in Article 130 – Work Involving Electrical Hazards

Article 130 includes several important revisions related to electric shock protection, arc-flash risk assessment, PPE requirements, and operational safety. These updates strengthen hazard evaluation and clarify when protective measures are required.

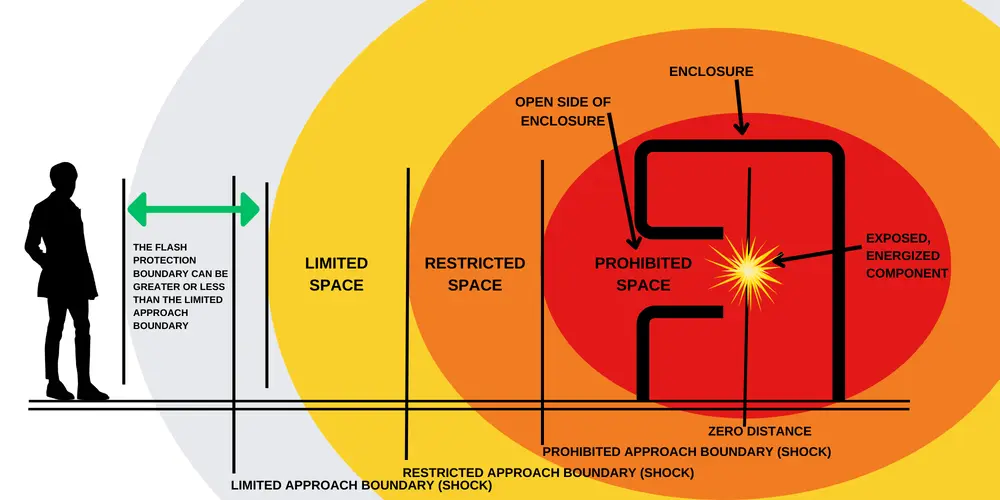

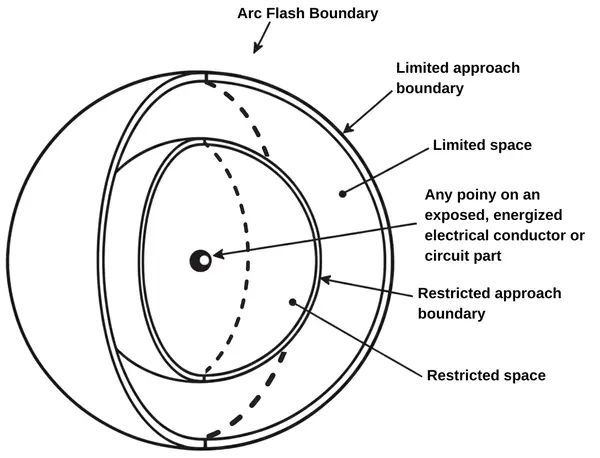

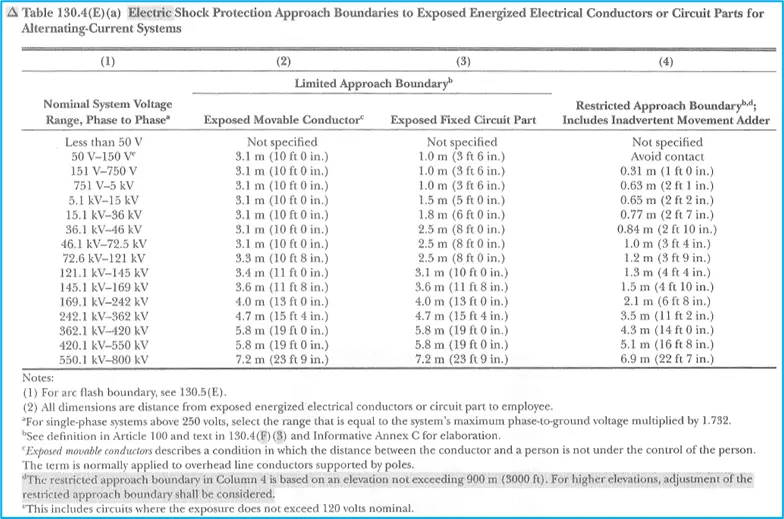

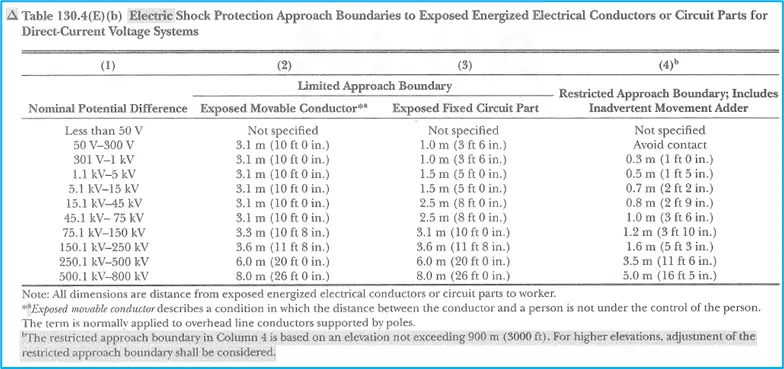

6.1 Electric Shock Protection Boundaries (130.4(E))

Key updates were made to the AC and DC shock protection boundary tables:

6.1.1 Revisions to AC and DC Tables

- Tables 130.4(E)(a) (AC) and 130.4(E)(b) (DC) were updated to align the Restricted Approach Boundary values with OSHA’s minimum approach distances found in OSHA 29 CFR 1910.269.

- Minor corrections were applied to the numerical values in Column 2 to resolve rounding discrepancies.

- Corresponding updates were also made in Annex C.2.1.

6.1.2 New Elevation Note Added

A new note clarifies that the Restricted Approach Boundary values are based on elevations up to 900 meters (3,000 feet).

At higher elevations—where air density decreases and dielectric strength drops—adjustments to the boundary must be considered.

6.2 Arc Flash Risk Assessment (130.5)

6.2.1 Likelihood and Severity (130.5(B))

Informational Note 2, previously located under DC PPE requirements, has been moved here.

It explains that closed equipment doors may not provide adequate protection, and may fail or open during an arc-flash event unless the equipment is arc-resistant.

This clarification now applies broadly to all arc-flash risk assessments, not just DC systems.

6.2.2 Updates to Table 130.5(C)

The column previously labeled “Equipment Condition” has been renamed “Operating Condition” to align terminology with the “normal operating condition” requirements found in Article 110.

This reinforces the connection between equipment condition, operation, and hazard likelihood.

6.2.3 Incident Energy Analysis Method (130.5(G))

A new informational note emphasizes that changes to the electrical system can affect the accuracy of an incident energy analysis. Examples include:

- Changes in transformer size

- Adjustments to protective device settings

- Replacement or modification of protective devices

- Utility-side configuration changes

Such changes may alter system fault current levels or protection clearing times, potentially requiring the incident energy analysis to be updated.

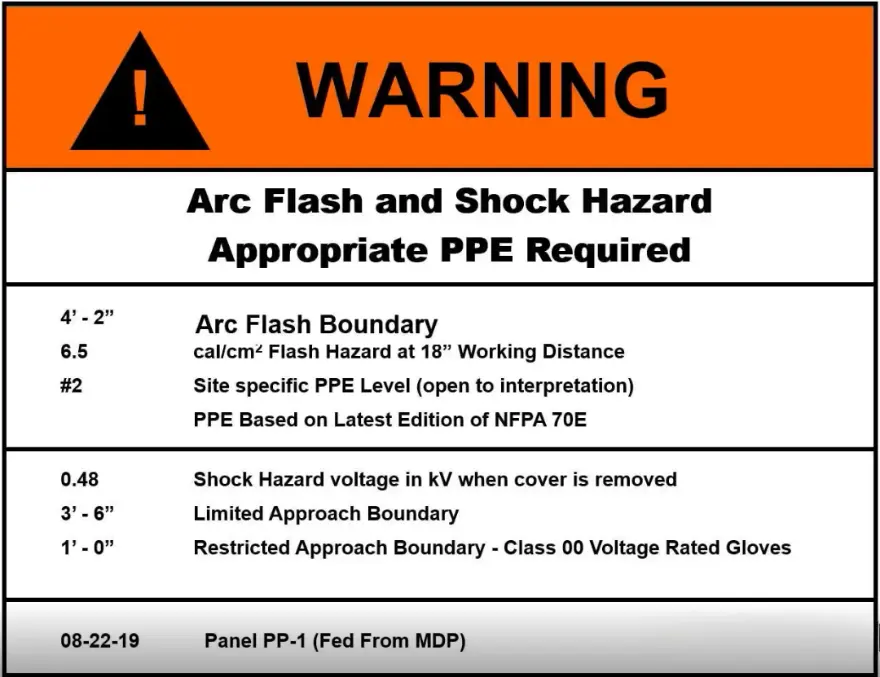

6.2.4 Equipment Labeling Requirements (130.5(H))

For example, arc-flash labels like the one shown include the arc-flash boundary, incident energy or PPE requirement, nominal voltage, and shock approach boundaries. The 2024 edition clarifies that these labels must also be durable for the installed environment, accounting for factors such as UV exposure, moisture, chemicals, and industrial wear.

6.3 Personal Protective Equipment (130.7(C))

6.3.1 General PPE Updates — Informational Note 1

The reference to acceptable risk-reduction methods has been updated to recognize:

- Noncontact capacitive test instruments, and

- Permanently installed metering devices

The previous 1,000-volt limit was removed since these methods may apply at lower or higher voltage levels.

6.3.2 Hearing Protection Requirements (130.7(C)(5))

The word “working” was removed from the text.

Hearing protection is now required whenever a person is inside the arc-flash boundary, regardless of whether any active work is being performed.

6.3.3 Updated Terminology for Rubber Glove Requirements (130.7(C)(7)(a))

The term “gauntlet” was replaced with clearer wording:

- Minimum distance between the protective cuff and the rubber insulating glove cuff.”

This update improves understanding of proper glove configuration.

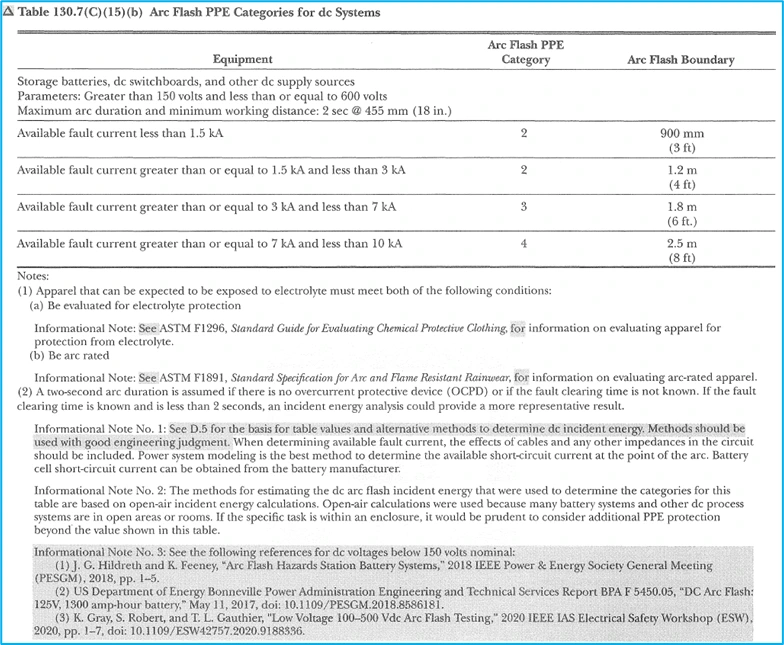

6.3.4 Major Revision to DC PPE Table (Table 130.7(C)(15)(b))

Significant changes were made to the DC PPE Category table:

- The previous range of 100–250 V DC has been removed.

- The new applicable range is:

>150 V DC and <600 V DC.

This change is based on modern test data showing:

- 125 V DC systems have minimal likelihood of sustaining an arc when fault currents are below 17,000 A.

6.4 Reclosing Circuits After Protective Operation (130.8(M))

Updates clarify when circuits may be manually re-energized:

- A circuit must not be manually re-energized until a qualified person determines that it is safe to energize.

- The word “repetitive” was removed to eliminate the misunderstanding that one reset attempt may be permissible before investigation.

- Overload-related operations have been moved into an exception for clarity.

7. New Informative Annex S – Assessing Condition of Maintenance

The 2024 NFPA 70E introduces Informative Annex S, providing optional guidance for qualified workers to evaluate electrical equipment maintenance, helping identify risks that heighten arc flash and shock hazards.

One key tool? Infrared thermography, which detects hidden hot spots from loose connections or overloads, preventing failures and fires non-invasively.

Curious how it reveals invisible heat threats? Learn more: How Does Infrared Thermography Work.

With the 2024 edition published, the 2027 revision cycle is underway—got ideas? Submit public input: How Do I Submit a Public Input on an NFPA Standard.

The 2024 edition of NFPA 70E reinforces a critical message: electrical safety relies on clarity, proper maintenance, accurate risk assessment, and disciplined work practices, with key updates addressing definitions, ESWC procedures, shock and arc-flash boundaries, PPE requirements, and the introduction of Annex S for maintenance assessment. At AllumiaX, we translate these standards into actionable solutions by providing expert arc-flash studies, short-circuit and coordination analysis, PPE labeling, power-system design, and maintenance-focused engineering—ensuring facilities not only achieve compliance but also strengthen safety through practical, reliable, and well-structured practices.

Stay Sharp & Join our Mailing List!

Subscribe to Allumiax Blog for updates on power system studies, tips, guides and insights on electrical engineering from industry leaders.