Methods of Solar Power Generation

Sun being the infinite source of power, Solar Energy is considered a power source that won’t ever run out. We have multiple energy resources, and most of them are running out as the demand for power increases with the advancement of technology, industrialization, and urbanization. If all the non-renewable energy resources run out, the sun itself would be enough to serve the power demand of the whole world. As time passes by, we are already running out of conventional energy resources, and this signifies how important it is for us to focus on the development of systems that are solely dependent upon Solar Power. This article focuses on the different methods of Power generation through solar energy and discusses the significance and scope of the most advanced and commonly used methods, throughout the globe.

Sources of Solar Power:

Sources of Solar Power can be widely categorized into Solar Photovoltaic modules and Solar Thermal Power.

Photovoltaic modules Based on the type of crystal used, commercially available PV technologies being used in power systems today can be classified into the following types:

- Crystalline PV cells

- Non-crystalline PV cells

- Hetero junction cells

Crystalline PV cells:

Crystalline PV modules are made by grouping several individual crystalline silicon solar cells (c-Si) which are in fact silicon atoms combined in the form of a crystal lattice. These are currently the most used type of modules being used frequently for both residential as well as commercial systems due to their higher efficiencies than the other PV technologies.

Crystalline PV cells can be further categorized into two kinds:

- Monocrystalline cells

- Polycrystalline cells

Monocrystalline cells:

Monocrystalline solar cells are those in which each cell is made of a single silicon crystal. These cells have a black hue with rounded edges. Their dark appearance is due to how photons interact with the pure silicon crystal. They have higher energy conversion efficiency than an equally powered polycrystalline solar panel and thus are more space efficient. However, due to the adequate functionality it offers, it is more expensive. It has a high-temperature coefficient which makes it less affected by changes in temperature.

Polycrystalline cells:

Multiple silicon fragments are melted together to produce the wafers of a multi or polycrystalline cell. They tend to have a bluish hue. The electrons in the cell have lesser space to flow due to multiple crystals in the cell thus making this kind less efficient as compared to the monocrystalline solar cells. But are more affordable for consumers. So, if you don’t have a limitation of space, polycrystalline panels might work well to provide the same output power with a couple more panels. The temperature coefficient of polycrystalline cells is lower implying their efficiencies decrease for every one-degree rise in temperature than the panel-rated temperature (usually 25 degrees Celsius or 77 degrees Fahrenheit).

Non-crystalline PV Modules (Thin Film)

Thin Film solar panels are non-crystalline and comprise of multiple thin layers of PV materials. These are flexible and light weighted. Depending on what they are made from, thin film panels come in both black and blue hues. Thin Film cells deposit a material that can produce a PV effect on a backing medium called a substrate. The substrate can be a glass sheet, PVC roofing material, foil sheet, etc. The name thin film in fact implies that the substrate material is really thin ranging from just nanometers to a few micrometers thick. They cost less than traditional solar PV technology but require large space for installation. Thus, are not recommended for residential systems.

On the basis of the type of substrate used, there are 4 most commonly used types of thin film panels.

- Cadmium Telluride (CdTe): A very thin layer of CdTe merely micrometers thick is deposited onto the substrate (usually glass). Another glass sheet is adhered to the first for the protection of the cells thus making these types of thin film panels to be used in place of conventional windows too. The cost of the raw materials used to manufacture this type is very low implying its economic feasibility. However, keeping in mind the fact that tellurium is a rare earth element, mass production of these panels might not be reasonable.

- Amorphous silicon (a-Si): It is the most prevalent type of thin film module. a-Si has the ability to be combined with non-rigid substrates such as flexible vinyl sheets or PVC roofing materials. This allows a-Si PV modules to be largely used for commercial flat roofs or building integrated photovoltaics. It is an attractive option in terms of aesthetics as well as cost when installed on a relatively larger surface area.

- Copper Indium Gallium Selenide (CIGS): This type uses four different raw materials, and the substrate material can be both flexible and rigid. It can be manufactured with a few nanometers of the material deposited on the substrate, due to which it has gained popularity in recent years. Less manufacturing material usage reduces cost without reducing efficiency. The cells are manufactured in the form of cylindrical tubes which makes them perpendicular to the sun for longer periods of time, thus increasing energy production.

- Gallium Arsenide (GaAs): Thin-film solar panels made with Gallium Arsenide are deemed to be the most efficient of all thin-film panels. However, because of their high costs, they are usually used in developing spacecraft and other types of specialized applications where PV energy is essential.

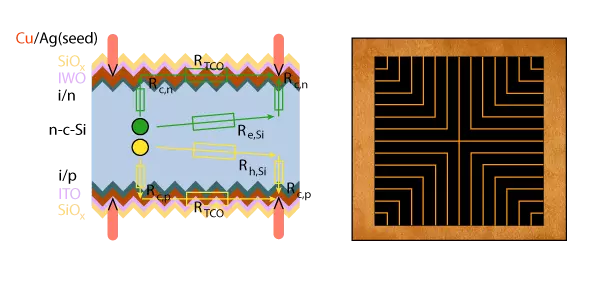

Hetero Junction cells:

Solar cells that are developed by the conjunction of crystalline technology with thin film technology are called heterojunction cells. This technique increases the overall efficiency as well as the power output as it combines the strengths of both and improves the lifespan of the modules. However, making them costly to purchase but otherwise pertains to a decreased Levelized Cost of Energy (LCOE).

They are typically used in high-visibility applications such as solar awnings or patio covers. This technology is less affected by the changes in temperature making it useful for higher temperature locations.

Following are the three commonly used materials for HJT cells:

- Crystalline Silicon (c-Si)

- Amorphous Silicon (a-Si)

- Indium Tin Oxide (ITO)

Comparison of Different Types of PV Solar Technologies:

The table below shows a comparison between different types of commercially available PV technologies.

|

TYPE OF PV TECHNOLOGY |

MONOCRYSTALLINE |

POLYCRYSTALLINE |

THIN FILM |

HETEROJUNCTION |

|

INITIAL COST |

High |

Moderate |

GaAs types are costlier than crystalline types. |

High |

|

EFFICIENCY (Average) |

≥ 20% |

15-17% |

≥ GaAs: 30% |

≥ 22% |

|

APPEARANCE |

Black with rounded edges |

Blue with square edges |

Depends on the thin-film variant |

Depends on the outer layer material |

|

TEMPERATURE COEFFICIENT (Average) |

Low-temperature coefficients in range of 0.36 to 0.40 % /°C |

Slightly higher temperature coefficients in range of 0.39 to 0.43 % /°C |

Low-temperature coefficients closer to - 0.2% / °C |

Low-temperature coefficients closer to - 0.3% / °C (depends on the junction cell types) |

|

PROS |

Space efficient, improved performance in high temperatures |

Cost friendly, it is a balanced option in terms of capacity, cost, and efficiency |

Easy to install and flexible. improved performance in high temperatures |

a decreased Levelized Cost of Energy (LCOE), improved performance in high temperatures. |

|

CONS |

High initial cost, Low yield in the manufacturing process. |

Low heat tolerance, not suitable in hot environments |

Shorter lifespan requires more space, least efficient except in case of GaAS PV modules |

Higher costs and incompatible production lines |

Solar Technologies Based on Thermal Power (Solar Thermal):

- Flat plate collectors

- Evacuated tube collectors

- Concentrating Solar Power (CSP) Technology

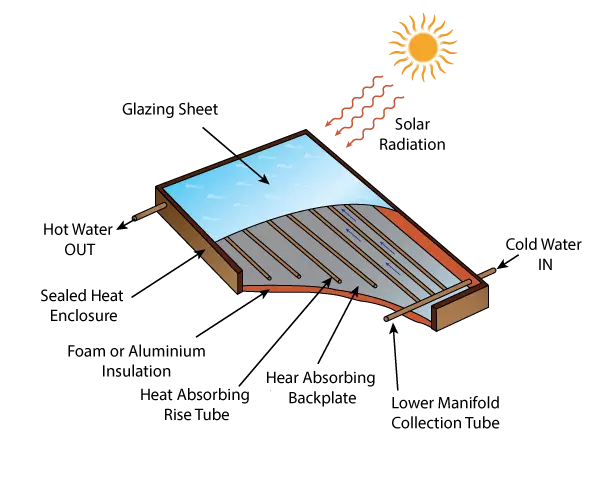

Flat Plate Collectors:

A flat plate collector is simply a flat rectangular box, with a layer of glazing sheet to avoid heat loss, a fluid inlet, and an outlet, tubes arranged in parallel through which the fluid flows. The ‘Heat Absorbing Plate’ placed at the bottom absorbs the sun’s heat and efficiently transfers it to the water running through the tubes. Usually, flat plate collectors provide temperatures up to 100 degrees Celsius. This can be utilized for different domestic and industrial applications. Air and water both can be used in flat plate collectors as working fluids, although it’s not used for the sake of power generation, but just to provide effective means of saving energy.

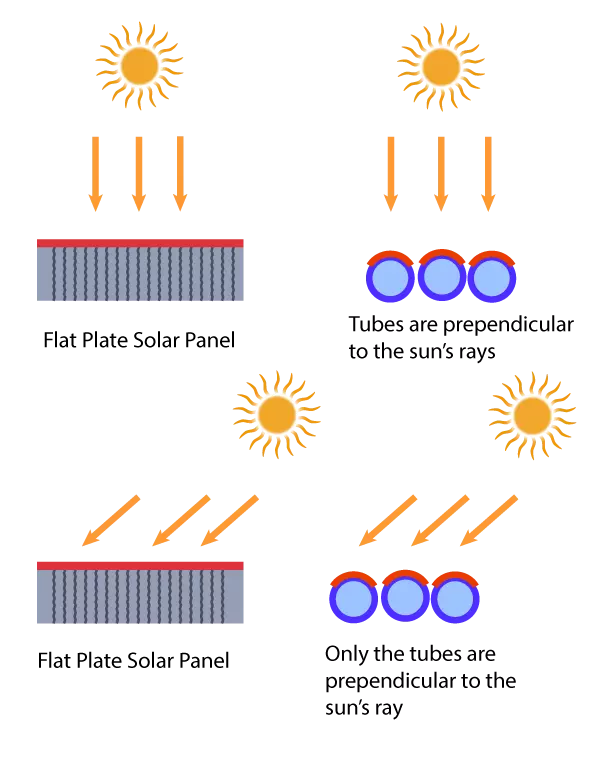

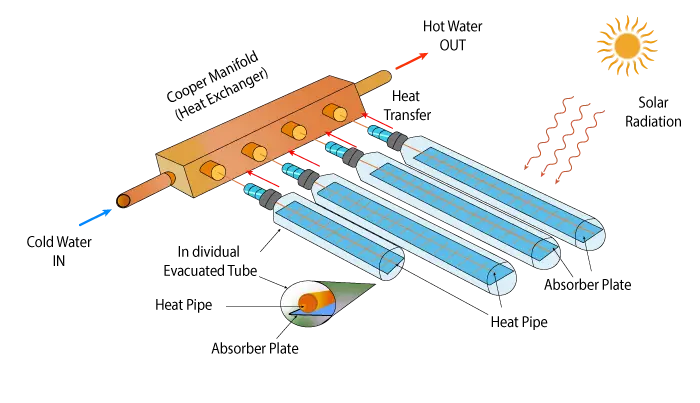

Evacuated Tube Collectors:

The Evacuated Tube Collectors work in a similar way to a Flat Plate collector, but their components are slightly different which enables them to yield higher efficiency. Unlike Flat Plat collectors, evacuated Tube collectors do not have Flat plates, and each of its pipes has its Individual heat transfer fin and Evacuated tube. As a result of this tubular structure, its capable of facing the sun directly from all locations, while flat plate collectors only receive direct irradiance when the sun is facing it perpendicularly, this attribute of evacuated tube collectors helps them to work at a higher efficiency.

Heat pipes contain evaporating and condensing liquids that absorb heat and release it to the heat sink region. This heat is absorbed by the water or any system fluid in the header pipe which is then utilized for the designated purpose.

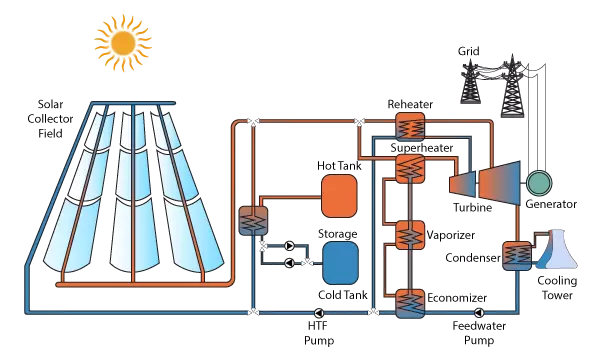

Concentrated Solar Power (CSP):

Concentrated Solar Power is a different technology than Photovoltaic Systems, and it depends upon using the sun’s Heat Energy to Generate Power. In concentrated Solar Power Systems, huge mirrors are used to concentrate the sun’s light at one point. The working fluid absorbs a high amount of heat energy, which is being focused at one point, this energy is further used to fuel steam turbines and heat engines.

Following are the types of concentrated systems:

- Parabolic Troughs

- Solar Dish/Parabolic Dish

- Solar Power Tower

- Linear Fresnel Reflectors

The availability of sun is limited to only in day times, which would limit the performance of a system if we would be completely dependent on the CSP. Therefore, generally, CSP is integrated into the systems where we can also have other means of heating available so that the system would be capable of working in all circumstances.

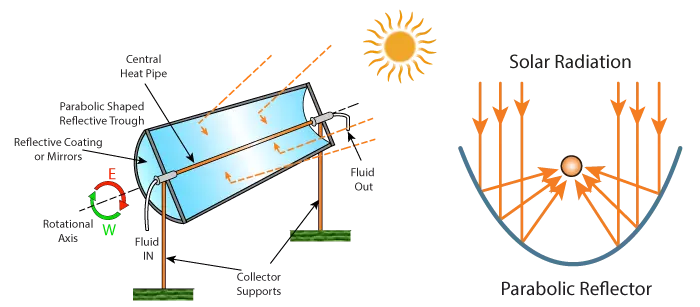

Parabolic Troughs:

A parabolic trough is a ‘U-shaped’ structure, with mirrors placed inside of it. The Central Heating pipe is present in the middle of this structure, all the sunlight that hits the collector mirrors is reflected to the heating pipe. The rotational axis of this parabolic trough is around the heating pipe, and it rotates around its axis to track the location of the sun.

The Central heat pipes are 70mm Heat Collectors, which are surrounded by Vacuum Jackets for the sake of insulation. Vacuum Jackets minimize the heat loss from the Heat transfer fluid. The heat transfer being used here is generally mineral oil or synthetic oil. This fluid goes to a heat exchanger where steam is produced, this steam is used in a conventional reheat steam turbine-generator to produce electricity.

Linear Fresnel Reflectors:

‘Linear Fresnel reflectors’ is a kind of Concentrated Solar Power Technology; it has several plain mirrors that are used to concentrate sunlight onto a tube that carries a working fluid that absorbs heat which is further utilized to produce steam. This steam is then used to drive a steam turbine.

The temperature of steam can vary from 290 to 390, while its concentration ratio is between 25 to 100.

Parabolic Dish:

A Parabolic Dish or Solar Dish has a structure very similar to Radar Dish. It has numerous small mirrors placed over it, which reflect the sunlight at a point where all the heat is absorbed by the working gas. The thermal energy absorbed by the liquid is much higher in comparison to the Parabolic Trough, as all the mirrors being used here act as separate objects focusing light at one point therefore it happens to have a 20 percent higher efficiency and is relatively easy to maintain. These small mirrors that are called ‘facets’ can be easily cleaned and are easier to replace in case of damage.

These several mirrors add up to make a large aperture area while the receiver consists of a small area, this feature enables Parabolic dishes to have exceptionally high concentration ratios up to 3000, and temperatures ranging up to 1500 degrees Celsius. While the temperature of the heat transfer fluid is from 550 to 750 degrees Celsius. The working gas in Parabolic dishes is usually ‘Helium’ or ‘Hydrogen’, although air can also be used as a counterpart. Unlike all other Concentrated Solar Power Technologies, Sterling Engine is used in the Parabolic dishes. Sterling Engine is different from Rankine’s Cycle as it is based on the compression and expansion of air at different temperatures, through which it generates mechanical Energy which is further converted into Electrical Energy.

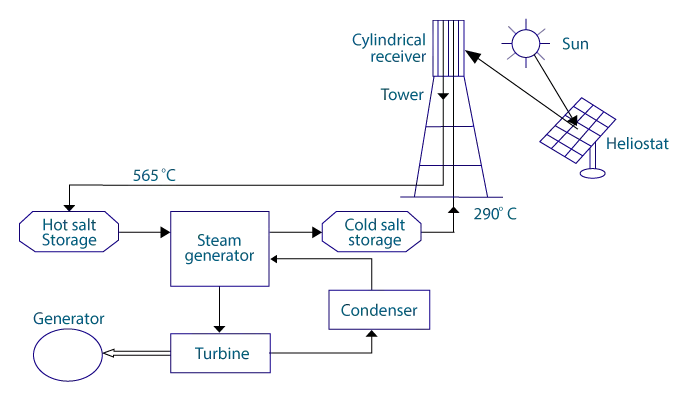

Solar Power Tower:

A Solar Power Tower is surrounded by huge rotating mirrors which track the location of the sun and reflects the sun’s heat to the receiver placed on the top of the Solar Power tower. The receiver contains “Molten Salt” also called nitrate salt (60% NaNO3 and 40% KNO3) which absorbs the suns heat, which can either be stored or used to produce electricity. Molten Salt is used in Solar Power Tower as a working fluid due to its capability of heat transfer and retaining heat for a longer period. Molten salts are usually Solid at room temperature, but as it absorbs heat it gets liquified, and then it is utilized for the sake of power generation.

Following are the main components of a Solar Tower Power Generation system:

The salt is moved from a Cold Storage tank to the cylindrical receiver where it absorbs the sun’s heat. This salt with a high amount of thermal energy stored in it is then brought to the Hot Storage tank, where it is stored until the power needs to be supplied to the grid. Then it is moved from the Hot Salt Storage to the steam generator, where it provides temperatures up to 565 degrees Celsius and generates steam. This steam is further utilized to run the Steam turbine. The salt that now has deposited its thermal energy in the steam generator is now collected in the Cold Storage tank, and the cycle repeats itself.

AllumiaX is a licensed Engineering company headquartered in Seattle, Washington USA. We work with sub-contractors to deliver various Power System Engineering studies including DC arc flash and DC short circuit studies for your Solar system. Get in touch with us at support@allumiax.com

Stay Sharp & Join our Mailing List!

Subscribe to Allumiax Blog for updates on power system studies, tips, guides and insights on electrical engineering from industry leaders.